Production of various high-end fabrics reaches 7 million meters annually, including a wide range of fashionable new products and exquisite items, with a broad coverage of color patterns.

Cotton Prepared For Dyeing Cloth Suppliers

-

Quick View

GS3019 Cotton Jacquard Dyed Fabric

-

Quick View

GS3224 Cotton Heavy Dyed Cloth

-

Quick View

GS4660 Cotton Prepared Dyed Printed Fabric

-

Quick View

GS20037 Cotton Slub Jacquard Dyed Fabric

-

Quick View

GS3509 Thin Dyed Stretch Poplin Fabric

-

Quick View

GS3270 Cotton Elastic Milled And Dyed Dobby Fabric

-

Quick View

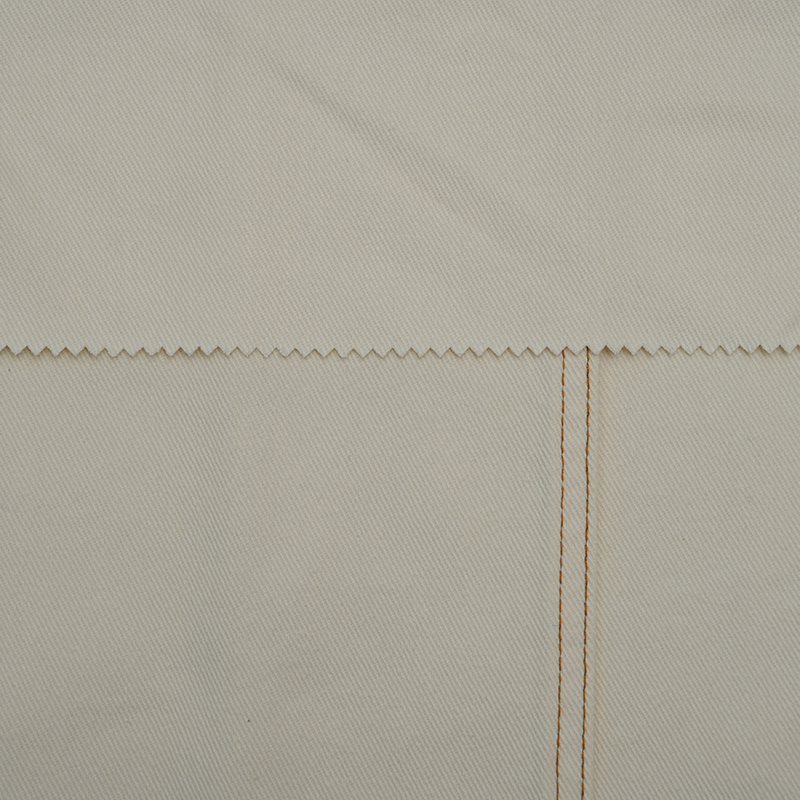

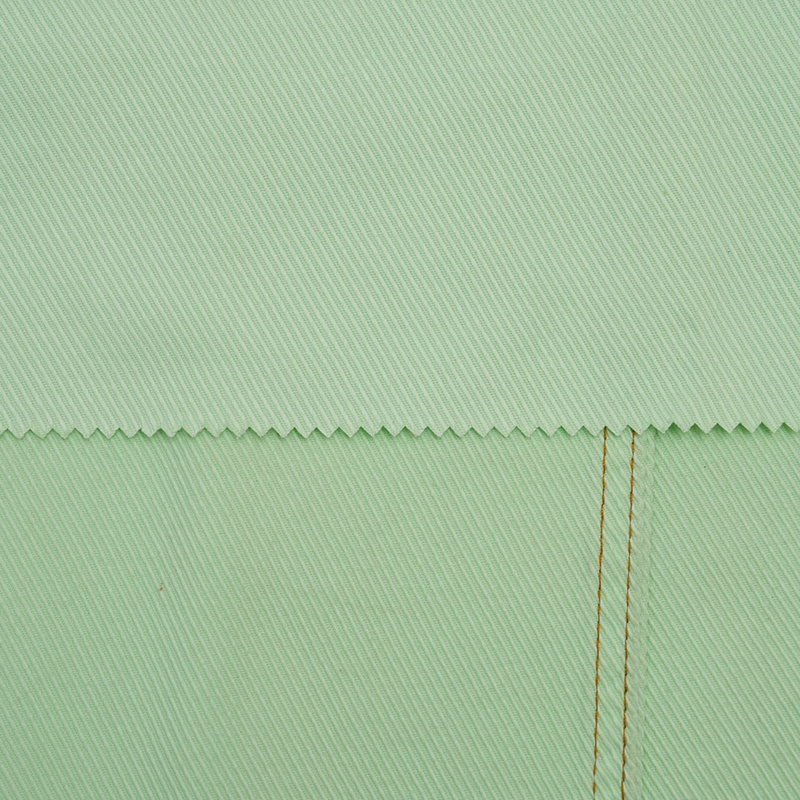

GS2300 All Cotton Cavalry Slanted Dyed Cloth

Cotton is prepared for dyeing cloth, which has a shorter production cycle and is more suitable for fast selling brands and e-commerce.

Changzhou Huiya Textile Co., Ltd.

AUTHENTIC RELIABLE QUALITY NATURALLYSTANDS OUT AND FEARS No COMPARISON.

We specialize in high-quality textiles and decorations and place a high value on product quality certification. To give customers confidence in our products, we'll keep working to raise their quality, offer them better products and services, and actively support the development of quality management systems.

-

1

Scope Certificate

-

2

Cotton Council International Certifies That

-

Corduroy Dyed Fabric: Types, Techniques & What to Expect

Corduroy dyed fabric achieves its best results when the dyeing method matches the fiber content — c...

READ MORE -

Woven Fabric: Types, Properties, and Manufacturing Process Guide

What Makes Woven Fabric Different Woven fabric is created by interlacing two sets of yarns at right...

READ MORE -

Eco-Friendly Dyed Fabric: Sustainable Dyeing Methods & Benefits

What Makes Fabric Dyeing Eco-Friendly Eco-friendly dyed fabric refers to textiles colored using met...

READ MORE -

What is Corduroy Fabric? Complete Guide to Properties & Care

Corduroy is a durable textile with distinctive parallel ridges or "wales" formed by vertical pile r...

READ MORE

Is Cotton Prepared for Dyeing Cloth from Changzhou Huiya Textile Co., Ltd. Suitable for Reactive Dyeing, Vat Dyeing, or Pigment Dyeing?

In today’s fast-paced textile market, adaptability is not just a strength—it’s a necessity. Whether catering to the precision demands of high-end apparel or the rapid delivery schedules of e-commerce fashion, textile suppliers must provide versatile, high-performance solutions. Among these solutions, cotton prepared for dyeing cloth has emerged as a cornerstone for efficient and flexible dyeing operations. And few manufacturers deliver this material with more technical prowess and industry credibility than Changzhou Huiya Textile Co., Ltd.

A Leader in Textile Innovation

Established in 2005 and rooted in the dynamic industrial hub of Changzhou, in the heart of the Yangtze River Delta, Changzhou Huiya Textile Co., Ltd. stands as a paragon of textile manufacturing excellence. This region, affectionately dubbed the "Land of Fish and Rice," has long been a cradle of commerce and craftsmanship—a heritage that Huiya has inherited and elevated.

Occupying over 12,000 square meters, with a modernized factory footprint of 11,000 square meters, Huiya’s facilities represent a fusion of tradition and advanced manufacturing. The company’s fully integrated operations—spinning, weaving, dyeing, and finishing—allow for total quality control across every stage of production.

With an annual capacity of over 7 million meters of premium fabrics, Changzhou Huiya is not merely a supplier, but a strategic partner to global clients seeking consistency, innovation, and speed. From boutique fashion houses to mass-market retailers, customers rely on Huiya’s ability to marry aesthetics with performance.

Tailored for the Modern Supply Chain

What sets Huiya’s cotton prepared for dyeing cloth apart is its exceptional readiness for a variety of dyeing methods—particularly reactive, vat, and pigment dyeing.

These dyeing techniques each serve a distinct purpose:

Reactive Dyeing bonds chemically with cotton fibers, resulting in brilliant colorfastness and durability. Huiya’s PFD fabric, with its clean, absorbent surface and minimal residual chemicals, is engineered to embrace this dye type flawlessly.

Vat Dyeing, ideal for deep, rich hues and industrial-grade wash fastness, demands a high-quality cotton base that can withstand the rigorous oxidizing and reducing conditions involved. Huiya’s controlled preparation process ensures the fabric’s stability and uniformity during this complex method.

Pigment Dyeing, often favored for fashion-forward, washed-out effects and artistic coloration, requires a fabric surface that allows for even pigment adhesion. The smooth hand feel and consistent weave of Huiya’s PFD cotton make it an ideal substrate.

Whether the objective is vivid, long-lasting color or trend-driven aesthetics, this fabric performs with remarkable adaptability.

The Competitive Edge for Fast-Selling Brands

In an era where fashion trends change overnight, production timelines can no longer afford delays. Changzhou Huiya’s PFD cotton fabric supports a shorter production cycle, enabling brands—especially fast-fashion and online retailers—to move from concept to finished product with agility.

The fabric’s readiness for immediate dyeing eliminates unnecessary processing steps, reducing lead times without compromising quality. For companies operating on a just-in-time model, this is not just convenient—it’s mission-critical.

Sustainability with Substance

Modern consumers demand more than style—they want responsibility. Huiya recognizes this shift and responds with a product line that balances performance, environmental integrity, and recyclability. Its cotton fabrics are produced with advanced equipment and environmentally conscious processes, designed to minimize waste and support closed-loop production systems.

From fiber selection to finished cloth, every step is aligned with international standards for ecological safety and sustainability.

So, is cotton prepared for dyeing cloth from Changzhou Huiya Textile Co., Ltd. suitable for reactive dyeing, vat dyeing, or pigment dyeing?

Absolutely. More than suitable, it’s optimized for them.

With a forward-thinking approach, meticulous manufacturing, and a commitment to excellence, Huiya delivers a textile solution that checks every box—technical, commercial, and environmental. For brands looking to dye smarter, faster, and better, this is where your color story begins.

English

English 中文简体

中文简体 Tiếng Việt

Tiếng Việt