Production of various high-end fabrics reaches 7 million meters annually, including a wide range of fashionable new products and exquisite items, with a broad coverage of color patterns.

What is PFD Fabric? A Complete Guide to Preparing for Dyeing

2025-12-05

If you’re a crafter, textile artist, or small-scale clothing designer diving into the world of dyeing, you’ve likely encountered a frustrating problem. You meticulously follow a dye tutorial, only to end up with a splotchy, uneven color that doesn’t match your expectations. Often, the issue isn’t your technique—it’s your starting material. This is where the concept of PFD fabric becomes essential.

What Does PFD Mean?

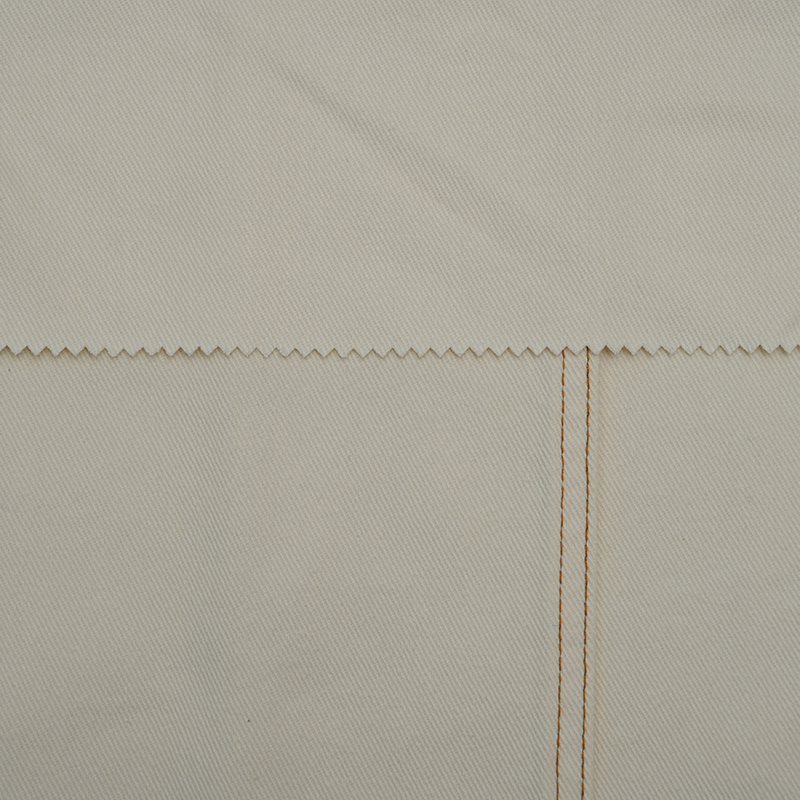

PFD is an acronym for Prepared For Dyeing. It refers to a greige good (a term for unfinished textiles) that has been specially manufactured and processed to be exceptionally receptive to dye.

Unlike the fabric you buy off the bolt at a local craft store, PFD cloth has not gone through the standard finishing processes. This intentional lack of treatment is what makes it so valuable for dyeing projects.

Why Standard Fabrics Fight the Dyeing Process

To understand why PFD is superior, it helps to know what’s on the fabric you typically buy. Most commercially available cotton, linen, and rayon fabrics undergo several finishing treatments:

- Sizing and Starches: Applied to add body, weight, and stiffness to make the fabric easier to cut and sew on industrial equipment.

- Optical Brighteners: Chemical compounds that make fabric appear brighter and whiter by converting UV light into visible blue light. They are notorious for interfering with dye, creating odd, muted, or off-tone colors.

- Softeners and Defoamers: Used to give the fabric a specific hand-feel right off the bolt.

- Dirt and Oils: From manufacturing and handling, these can create barriers for dye.

When you try to dye these treated fabrics, the dye cannot penetrate the fibers evenly. It bonds to the chemical finishes first, resulting in pale, patchy, and unreliable color. Prepared for dyeing fabric skips all of this, providing you with a perfectly blank, contaminant-free canvas.

Key Characteristics of PFD Material

How can you identify true PFD cloth? Look for these traits:

- It’s Usually Bleached, But Not Brightened: PFD fabric is often a bright white, but this is achieved through a bleaching process that removes the natural oils and tints of the raw fiber (like the yellowish hue of raw cotton) without adding optical brighteners. Some PFD fabric may be offered in its natural, unbleached state.

- It Has No Finishes: You won’t find any starches, softeners, or other chemicals. As a result, the fabric might feel a bit stiffer or crisper than you’re used to. This is normal and actually desirable.

- It’s Often 100% Natural Fiber: While synthetic PFD options exist, the term is most commonly associated with PFD cotton (especially jersey knit for apparel), linen, rayon, and silk. These natural and cellulose-based fibers have a natural affinity for many types of dye, like fiber reactive dyes, which produce vibrant, permanent colors.

- It’s Absorbent: A simple test is to drop water on the fabric. On PFD material, the water droplet will be wicked away and absorbed almost instantly. On a finished fabric, the droplet may bead up and sit on the surface.

The Practical Benefits of Using PFD Cloth

Choosing to work with PFD material offers several concrete advantages for your projects:

- Vibrant, True Color: Dye bonds directly and evenly with the fiber molecules, allowing the pigments to develop to their fullest, most intense potential. The color you see on the dye bottle is the color you’ll get.

- Even and Predictable Results: Say goodbye to splotches and uneven dyeing. PFD fabric ensures a uniform color from edge to edge, which is critical for large projects like dyeing clothing or quilting cotton.

- Superior Colorfastness: Because the dye bonds at a molecular level with the clean fiber, the resulting color is more durable and resistant to fading from washing and light exposure.

- Total Creative Control: You are not fighting against unknown chemical finishes. This allows you to have complete control over your final product, from the lightest pastel to the deepest, richest black.

How to Prepare and Dye PFD Fabric

Even though it’s “prepared,” a little extra prep on your part ensures the absolute best outcome.

- Scour (Wash) It: It’s a best practice to give PFD fabric a quick wash before dyeing. This removes any microscopic dust or oils it may have picked up during storage or shipping. Use a very hot wash with a dye-friendly surfactant like Synthrapol or a small amount of clear, blue Dawn dish soap. Avoid regular detergent, as it often contains brighteners and softeners. Do not use fabric softener.

- Keep It Wet: For most dye types, the fabric should be soaking wet before it enters the dye bath. This guarantees even saturation.

- Choose the Right Dye: PFD cotton, linen, and rayon work magnificently with fiber reactive dyes (like Procion MX dyes) for the most permanent and vibrant results. Acid dyes are ideal for PFD silk and wool. All-purpose dyes can work but may not offer the same intensity and wash-fastness.

- Follow Best Dyeing Practices: Use enough water, stir continuously, and allow the recommended amount of time for the dye bath to exhaust (all the color is absorbed from the water into the fabric).

Who Should Use PFD Fabric?

This material is not just for industrial use. It’s perfect for:

- Home Dyers looking to achieve professional, consistent results.

- Sewists and Fashion Designers who want to create custom-colored garments from scratch.

- Quilters seeking perfectly dyed fabric for their art pieces.

- Textile Artists and printmakers who use dye as their medium.

- Anyone interested in sustainable fashion and understanding the full lifecycle of their materials.

Finding and Selecting PFD Fabric

When searching for PFD material, look for suppliers that specialize in dyeing supplies or wholesale textiles. The product description should explicitly state “PFD,” “Prepared for Dyeing,” or “Free of Optical Brighteners.” Specify the fiber content you need, whether it’s PFD cotton jersey for t-shirts, PFD quilting cotton for crafts, or PFD linen for home decor.

In conclusion, using PFD fabric is the single most effective way to elevate your dyeing projects from amateur to expert. It removes the variables and unknowns, putting the power of vibrant, predictable, and beautiful color directly in your hands. By starting with a truly blank canvas, you ensure that your final creation is a perfect reflection of your vision.

English

English 中文简体

中文简体 Tiếng Việt

Tiếng Việt