Production of various high-end fabrics reaches 7 million meters annually, including a wide range of fashionable new products and exquisite items, with a broad coverage of color patterns.

How PFD Fabric Improves Color Absorption in Dyeing

2025-09-24

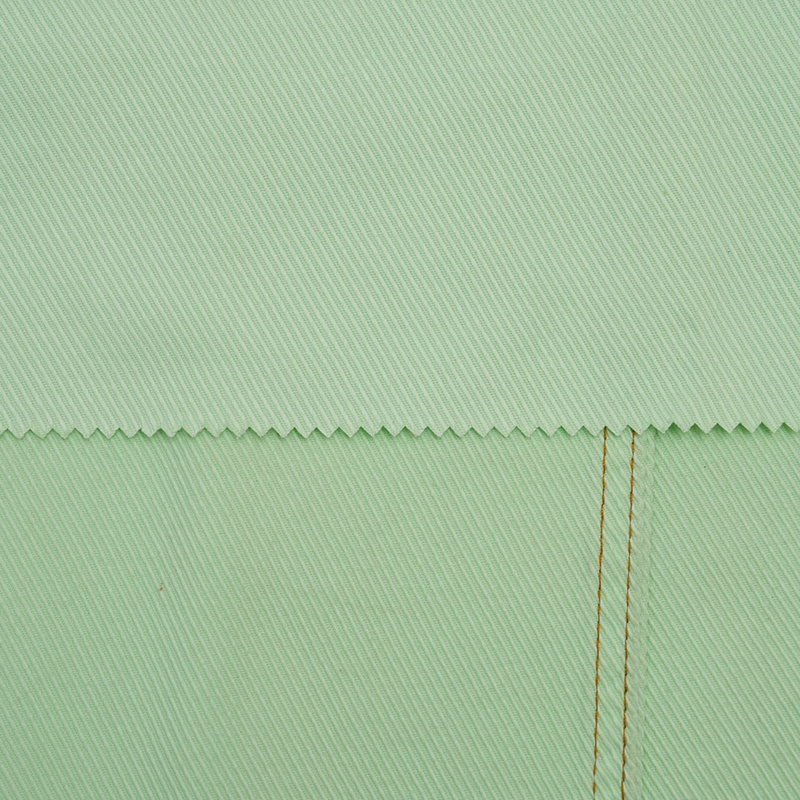

In the textile industry, color is more than decoration. It is a defining element that shapes how fabrics are perceived, used, and valued. The brilliance, consistency, and longevity of dyed textiles depend heavily on the type of fabric that undergoes the dyeing process. Among the many fabric preparations available, PFD fabric, short for Prepared For Dyeing fabric, plays a pivotal role in achieving optimal color absorption. Understanding what PFD fabric is and how it functions provides valuable insight into why it has become a cornerstone for designers, manufacturers, and artisans who require predictable and vibrant color results.

What Is PFD Fabric

PFD fabric refers to textiles that have been specially treated and finished to ensure they are ready to take dyes evenly and effectively. Unlike standard cotton or other untreated materials, PFD fabrics undergo processes that remove impurities, oils, waxes, and finishes that would otherwise resist dye penetration. This preparation creates a neutral, absorbent surface that enhances the interaction between dye molecules and fabric fibers. The result is improved dye uptake, consistent coloration, and reduced risk of uneven blotches or fading.

The Preparation Process

Before fabric earns the label of PFD, it passes through several preparatory stages. These processes include desizing, scouring, and bleaching, all of which contribute to the removal of contaminants.

Desizing eliminates starches and other sizing agents that may have been applied during weaving to strengthen fibers.

Scouring washes away natural oils, pectins, and waxes inherent in cotton and other fibers.

Bleaching gives the fabric a uniform base by removing natural coloration, ensuring that the subsequent dye process begins on a clean and neutral surface.

The outcome of these steps is a fabric stripped of obstacles that could hinder dye absorption, creating a blank canvas ready for color.

Why Impurities Affect Dye Absorption

Untreated fabrics often contain residues that create barriers between dye molecules and the fiber surface. Natural waxes can repel water based dyes, while residual starch or oils may cause uneven penetration. This leads to inconsistent shades, weak colorfastness, and a less professional final product. By contrast, PFD fabric eliminates these variables. With a purified fiber surface, dyes are absorbed more directly, leading to vibrant, long lasting colors.

Improved Fiber to Dye Interaction

One of the most important aspects of PFD fabric is its ability to create better bonds between fibers and dyes. When fibers are thoroughly cleaned and neutralized, dye molecules can attach more securely, whether through physical absorption or chemical bonding, depending on the type of dye used. This enhanced interaction is what makes colors appear more saturated and resistant to washing or exposure.

Uniform Color Distribution

A common challenge in dyeing untreated fabric is the occurrence of streaks or patchy coloration. PFD fabric reduces this risk significantly. Because the fabric surface is free of residues, dyes spread evenly across the textile, creating consistent shades throughout. This uniformity is especially important in applications where large quantities of fabric must be dyed to identical standards, such as in apparel manufacturing, upholstery, or quilting projects.

Versatility Across Dyeing Methods

PFD fabric is compatible with a wide range of dyeing techniques, including direct dyeing, fiber reactive dyeing, vat dyeing, and natural dyeing. In each of these processes, the prepared surface of PFD fabric improves dye absorption and reduces waste.

Direct dyes benefit from the even penetration that prevents fading lines.

Fiber reactive dyes form strong covalent bonds with the prepared fibers, creating brilliant and durable colors.

Vat dyes rely on a clean surface for proper oxidation and fixation.

Natural dyes achieve more vibrant results when applied to PFD fabric compared to untreated cloth.

This adaptability makes PFD fabric a valuable material across both traditional and modern dyeing practices.

Enhancing Color Vibrancy

Color vibrancy depends not only on the pigment itself but also on how well it integrates with the fabric structure. Because PFD fabric is free of interfering substances, colors appear brighter and more saturated. The clear base provided by the bleaching stage ensures that no underlying tint dulls the final shade. Designers and artisans can achieve a more accurate match to their intended palette, which is critical for both fashion applications and decorative textiles.

Consistency in Large Scale Production

For industrial textile producers, consistency is as important as vibrancy. Customers expect garments or home textiles to match perfectly in color across different batches. PFD fabric supports this demand by ensuring each roll or lot of fabric begins with the same neutral, prepared state. This reduces variability during dyeing and minimizes costly quality control issues.

Benefits for Small Scale and Artistic Projects

While PFD fabric is indispensable in large manufacturing settings, it also offers benefits for smaller scale dyeing projects. Artists and hobbyists working with tie dye, batik, or hand painting appreciate the predictable results that PFD fabric delivers. The prepared surface allows them to focus on creativity rather than worrying about uneven dyeing or poor color take up.

Longevity and Colorfastness

Improved dye absorption does more than enhance immediate appearance. It also contributes to the long term durability of the color. Fabrics dyed on PFD material tend to resist fading from washing, light exposure, or abrasion. Stronger fiber to dye bonds protect colors from premature dulling, which is particularly valuable in applications such as upholstery, workwear, and frequently laundered garments.

Supporting Eco Friendly Practices

Another overlooked advantage of PFD fabric lies in its environmental impact. Because the fabric accepts dye more readily, less dye and fewer chemical additives are required to achieve the desired shade. This can reduce water usage, chemical runoff, and overall environmental load during the dyeing process. In an era where sustainable practices are increasingly important, the efficiency of PFD fabric contributes to greener production methods.

Applications in Fashion and Beyond

PFD fabric finds widespread application in fashion, home textiles, and industrial products. In fashion, it allows designers to experiment with custom dye shades, garment dyeing, and digital textile printing. In home textiles, such as curtains or bedding, its ability to maintain vibrant and uniform colors is invaluable. In industrial contexts, PFD fabrics support applications where durability and colorfastness are critical, such as uniforms and outdoor fabrics.

Common Misconceptions About PFD Fabric

Despite its advantages, some misconceptions persist. One is the belief that PFD fabric is simply bleached fabric. While bleaching is part of the process, PFD preparation goes further by removing waxes and finishes that bleaching alone cannot eliminate. Another misconception is that PFD fabric is only useful for professional dye houses. In reality, its predictable performance makes it suitable for anyone seeking reliable color results, regardless of scale.

Limitations and Considerations

While PFD fabric improves color absorption, it is not without limitations. The quality of preparation can vary depending on the manufacturer, which means not all PFD fabrics are identical. Additionally, different fibers, such as cotton, silk, or blends, may respond differently to dyeing, even if they are prepared for dyeing. Proper selection of fabric and dye type remains essential to achieving the best outcomes.

The Future of PFD Fabric

As the textile industry evolves toward greater customization, sustainability, and digitalization, the importance of PFD fabric is likely to grow. Its compatibility with digital printing technologies, reduced environmental footprint, and ability to support creative design make it an increasingly valuable material. Continued innovations in preparation techniques may further improve its performance and expand its applications.

Conclusion

The quality of dyed textiles is not determined by colorants alone. The condition of the fabric before dyeing plays a decisive role in how colors are absorbed, displayed, and retained. PFD fabric provides an ideal foundation for dyeing by eliminating impurities and creating a receptive surface for dyes. This results in brighter colors, consistent shades, and enhanced durability. From large scale textile production to individual artistic projects, PFD fabric offers advantages that make it indispensable. Its role in improving color absorption underscores the broader principle that in textiles, preparation is as important as the final finish.

English

English 中文简体

中文简体 Tiếng Việt

Tiếng Việt